Management

President

Factory Manager

VISION

MHTL is committed to continuous improvement to become a leading plastic compounding company in Thailand and to provide maximum satisfaction to its customers and related persons with excellent products and services. Meanwhile, as we have dedicated ourselves to the development of Thai society.

To achieve such goal, we introduce and apply new knowledge, technologies and innovations that our employees have continuously learned and developed to achieve maximum potential.

MISSION

Improve and develop product quality and reduce delivery cast in order to serve customers’ needs promptly and constantly.

Dedicate to improving and developing organization structure and tools in order to respond to the changes according to customers’ needs also fully focus on employees training.

Comply with the Thai laws and regulations and pay attention to safety and good environment as well as transparent and fair corporate governance.

Establish team work of all employees by building trust, harmony and compliance with rules in order to enhance product quality, employee efficiency and competitiveness, which leads to the good performance.

HISTORY IN THAILAND

December 1988

We established Hexa Color (Thailand) Ltd. in Yannawa District of BKK.

August 1993

We moved from Yannawa district to Wellgrow Industrial Estate as new Factory.

January 1998

We started to produce GF-Compound.

September 2003

We expanded the factory as the second factory building.

June 2008

We expanded 3 machines at the second factory building .

January 2011

We changed company name to MEP Hexa (Thailand) Ltd.

COMPANY background

Shinya Fukui, the president of Hexa Chemical Ltd., founded Hexa Color (Thailand) Ltd. in December 1988. At that time, it was the first prosperous period for the Japanese businesses in Thailand. Since there were only two compound-related companies, it therefore became a big business by renting a small warehouse in Yannawa District, Bangkok, and installing two single-screw extruders. With twelve employees, it began doing master batches of PS ABS coloring in December 1989. After that, despite experiencing a domestic political crisis, the King helped solve the crisis and the plastic coloring and compounding industry was flourishing successively.

Since the company was always trusted by its customers, it could expand its business and add more machines with full production capacity.

In 1993, the company therefore moved its production base to 102 Moo 5, Wellgrow Industrial Estate, Bangna-Trad Road KM 36, Bangsamak, Bangpakong, Chachoengsao 24180, with more than 10 rai of total area, and its registered capital was added as 112 million baht.

MEP Hexa ( Thailand ) Ltd. is one of the leading businesses in the coloring and compounding of plastic in Thailand. We produce products that enter the market, both domestically and internationally through a network of more than 30 companies. We support our customers in the plastics manufacturing activities that have a network around the world. At the same time, we focus on the environmental impacts that may have from the production. Meanwhile, we focus on the impact and safety of customers and employees as well for our main goal is the quality of the product must meet the customer requirements, so that customers can continue to produce products to meet the standards of the global market.

HONOR

5S committees: 2006-2019

Zero Accident Award: 2012 Honorable Level

Zero Accident Award: 2013 Bronze Level

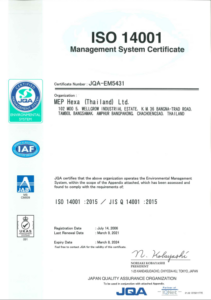

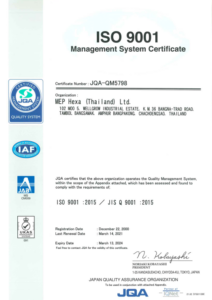

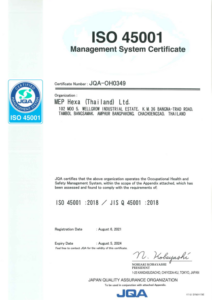

Certifications

Customer Requirement Supporting System

Canon : Green Procurements Standards

Omron : Quality partner certificate

Sony : Notification of Green Partner Certification